Title: “Revolutionizing Manufacturing: The Innovation of Injection Molds”

Injection molds have played a pivotal role in the manufacturing industry by revolutionizing the way products are produced. With the advancement of technology, injection molds have evolved to meet the growing demands of various industries. Injection mold factories and suppliers are at the forefront of this innovation, constantly pushing the boundaries of what is possible.

Injection mold factories are dedicated facilities equipped with state-of-the-art machinery and tools specifically designed for the production of high-quality molds. These factories often employ skilled engineers and technicians who have a deep understanding of the injection molding process. They work tirelessly to ensure that every mold produced meets the exact specifications and requirements of their clients.

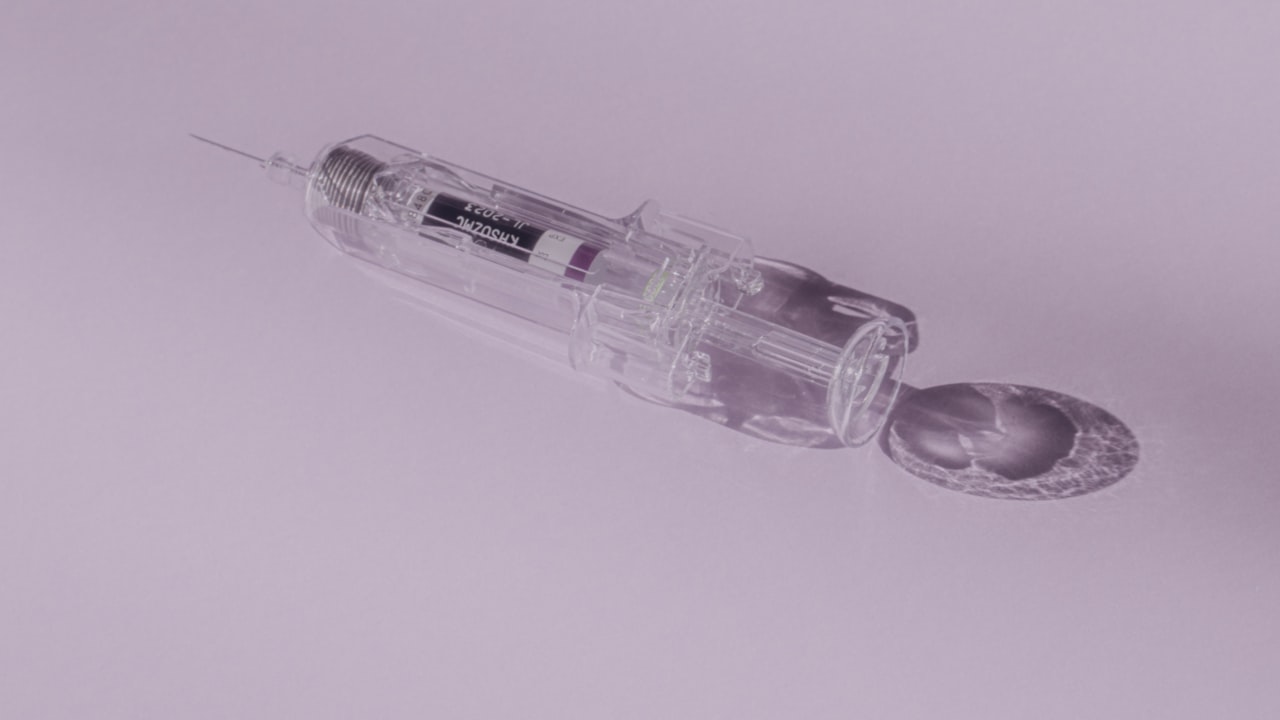

Injection mold suppliers play a crucial role in the industry by providing molds to manufacturers across different sectors. These suppliers work closely with their clients to design and produce molds that are tailored to their specific needs. Whether it is for automotive parts, consumer electronics, or medical devices, injection mold suppliers are essential partners in the manufacturing process.

The innovation of injection molds has led to significant improvements in efficiency and cost-effectiveness in the manufacturing industry. By using injection molds, manufacturers can create complex shapes and designs with high precision and consistency. This has enabled companies to produce products at a faster rate and with greater accuracy, leading to increased productivity and profitability.

Furthermore, injection molds have also contributed to the advancement of sustainable manufacturing practices. By optimizing the injection molding process, manufacturers can reduce waste and minimize environmental impact. Injection molds are designed to be durable and long-lasting, allowing for multiple uses and minimizing the need for frequent replacements.

In conclusion, the innovation of injection molds has transformed the manufacturing industry in profound ways. Injection mold factories and suppliers continue to drive this innovation forward, pushing the boundaries of what is possible and helping manufacturers achieve greater efficiency and sustainability in their production processes.

Title: “The Evolution of Injection Molds: Innovations and Applications”

Title: “The Evolution of Injection Molds: Innovations and Applications” Title: Advancements in Injection Moulds: Revolutionizing Manufacturing Processes

Title: Advancements in Injection Moulds: Revolutionizing Manufacturing Processes